Operations Management

Asset Management

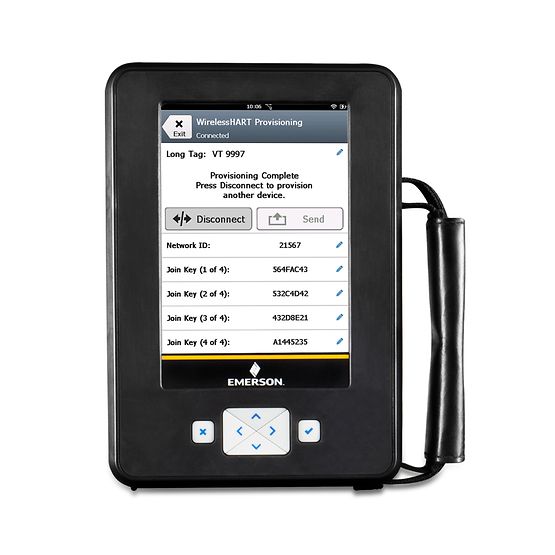

AMS Trex WirelessHART Provisioning App

The WirelessHART® Provisioning app allows you to provision wireless networks in less time, with less chance of error and in a more secure fashion. The app eliminates the need to open each device description, allowing you to enter the network ID and Joinkey once per network instead of for every device. Then, configure hundreds of devices with a push of a button, improving accuracy and allowing you to provision an entire network up to 6x faster.

Get Quote

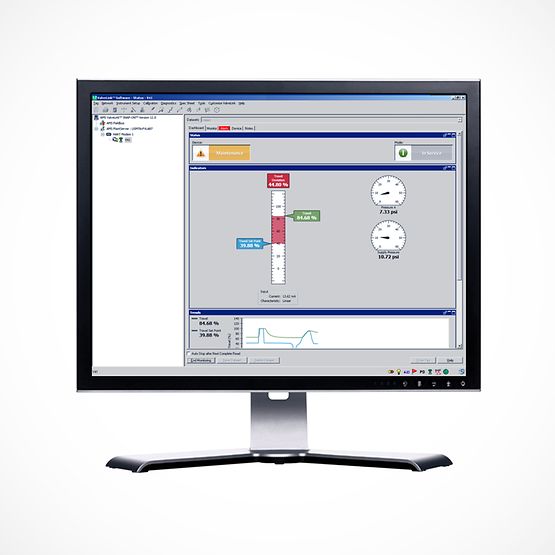

AMS Device Manager

Predictive maintenance helps plants avoid unplanned shutdowns and inefficient practices that eat away at profits. AMS Device Manager helps avoid these unnecessary costs with a window into the health of intelligent field devices. It gives your maintenance and operations personnel the ability to work smarter. Based on real-time condition data from your intelligent field devices, plant staff can respond fast and make informed decisions on whether to maintain or replace field devices.

Get Quote

AMS Device View

Through intuitive dashboards and focused alerts, quickly access the data you need to respond to issues effectively. AMS Device View extends your AMS Device Manager system by delivering device health and calibration status information through a browser-based interface. You gain insight into unhealthy devices from anywhere you have an internet connection.

Get Quote

AMS Wireless SNAP-ON

The AMS Wireless SNAP-ON application gives you more power to manage your wireless networks. Plan your networks and validate them against recommended design practices. After your wireless networks are installed, you can graphically view communication and status, allowing you to identify any potential trouble spots.

Get Quote

USB Fieldbus Interface

The USB Fieldbus Interface provides a convenient way to connect a desktop or laptop computer to Foundation fieldbus devices. When used with AMS Device Manager, the USB Fieldbus Interfaces allows you to commission, configure, and troubleshoot fieldbus devices both on the bench and in the field. It can also provide power to a fieldbus device or segment. The USB Fieldbus Interface can be used with an FDT frame application such as PACTware. It conforms to the Fieldbus Foundation physical layer standard as well as IEC standards for Emissions, Immunity, and Safety.

Get Quote

Valvelink SNAP-ON

AMS Device Manager allows easy access to powerful device diagnostics for configuration, calibration, and documentation of the operating characteristics of HART and Foundation fieldbus Fisher FIELDVUE digital valve controllers. Using the ValveLink SNAP-ON application, you can obtain valve diagnostics needed to solve problems before they affect the process. The ValveLink SNAP-ON application’s diagnostic capabilities permit you to select only those control valves that need to be rebuilt during plant turnarounds to optimize use of your valuable maintenance resources.

Get Quote

AMS 9420 Wireless Vibration Transmitter

The AMS 9420 Wireless Vibration Transmitter connects easily to any machine. It delivers vibration information over a highly-reliable, self-organizing wireless network for use by operations and maintenance personnel. The AMS 9420 is ideal for vibration monitoring applications, especially in hard-to-reach or cost prohibitive locations and it provides reliability with advanced accuracy for all installations.

Get Quote

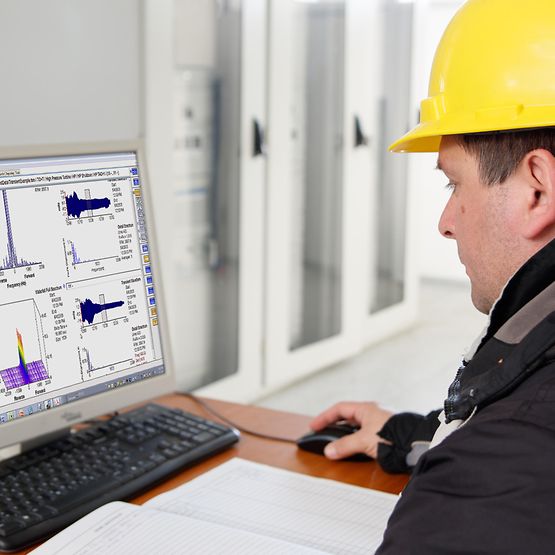

AMS 2140 Machinery Health Analyzer

The AMS 2140 Machinery Health Analyzer takes vibration data and analysis measurements to the next level. It features simultaneous four-channel plus phase data collection and unique peak detection capabilities for the earliest indication of bearing and gearbox degradation. In addition to delivering faster data collection for less time in the field or more machines monitored, the AMS 2140 is ergonomically designed for comfortable, single hand operation all day long.

Get Quote

AMS A6500-CC System Communication Card for AMS 6500 ATG

The ModBus and Rack Interface Module are designed for high reliability for the plant's most critical rotating machinery. It reads parameters from all AMS 6500 ATG modules and outputs these parameters through ModBus TCP/IP and/or ModBus RTU (serial). In addition, OPC UA is available for data transmissions to third party systems.

Get Quote

AMS A6500-SR System Rack for AMS 6500 ATG

The A6500-SR System Rack is part of the AMS 6500 ATG machinery protection system. It is a 19" rack (84HP width and 3RU height). The System Rack allows you to install up to 11 protection cards (two channel A6500-UM Universal Measuring Card and/or four channel A6500-TP Temperature Process Cards), one A6500-RC Relay Cards, and one A6500-Com Card - two Com Cards for redundant communication.

Get Quote

AMS Machinery Manager

AMS Machinery Manager integrates multiple predictive maintenance techniques with comprehensive analysis tools to provide easy and accurate assessment of the machinery health across different types of mechanical assets in your facility. The modular technology applications incorporate diagnostic and reporting sources into a common database for analysis of machinery health across the entire plant. Version 5.7 is now available for customers under Guardian Support.

Get Quote

A6560R Prediction Processor Card for the AMS 6500 Machinery Health Monitor

The A6560R processor is the heart of the AMS 6500 Machinery Health Monitor providing field-based predictive intelligence. An AMS 6500 is typically used, but not limited to, monitoring the mechanical health of rotating machinery by analyzing signals from vibration sensors mounted on the machine. The card’s FPGA and real-time prediction processor performs an overall continuous check of all input channels and generates detailed analysis on any two paired channels. The A6560R processor reports its results to AMS Machinery Manager for more detailed analysis, data archiving and reporting and can also provide preconfigured results via Modbus to any DCS or other Modbus enabled device. The A6560R comes standard with PeakVue technology and Modbus enabled and fully aligns with RoHS and REACH standards.

Get Quote

AMS 555 Vibration Strobe Light for use with AMS 2140

The AMS 555 Vibration Strobe Light allows for phase measurement without stopping the machine to install reflective tape. Built for rugged and portable applications, the AMS 555 provides accurate results and can be operated anywhere in the plant. Through freeze motion, operations and maintenance personnel can visually inspect high-speed rotating machinery with no stoppage to production.

Get QuoteOperations Management

Energy Management

How can industry make a step change in energy performance? Extracting value from applied industrial energy requires a holistic approach all along the value chain. Energy is purchased, converted, distributed, consumed, and sometimes exported on every industrial site . . . and the environmental, financial, and productivity impacts are significant and complex. Emerson industrial energy experts tame the complexity and improve business results. From the captive powerhouse to energy intensive process units, we have monitoring, control, and predictive solutions to optimize energy performance.

Get Quote

Manufacturing Execution Systems

Execute Effective Manufacturing with the Syncade MES The Syncade MES improves manufacturing operation to drive your production goals. Whether it is compliance regulations, excessive work in process, or inefficient use of resources, increasing production costs cut into your profits.

Get Quote

Reservoir Management Software

A Comprehensive Software Suite Placing uncertainty management at the heart of decision-making, our comprehensive software suite – from seismic interpretation to production management – helps operators make better decisions, leading to improved returns on investment. We deliver the confidence and understanding that enables operators to enhance oil & gas recovery and unlock the value of their assets. Our flagship products and solutions include RMS™, Tempest™, METTE™ and Big Loop™.

Get Quote

Upstream Applications for Oil and Gas

Replace Custom Programming with Pre-Configured Solutions Gone are the days of investing time and money to create custom programs for your operation. Our off-the-shelf application software will make your field operations more efficient by replacing custom programming with simple configurations. Simply select the application you need from our catalogue, load into your RTU, and start up faster. Add additional applications to scale up your operation, or change applications as your wells progress through the lifecycle-without changing hardware – maximizing scalability, profitability, safety, and efficiency.

Get Quote

Midstream Applications for Oil and Gas

Integrate business and operational data for maximum efficiency and revenue Keep your pipeline owner, terminal operator and chief financial officer aware of changing conditions with real-time, systems-level integration across the operational and commercial processes. Our automation and software applications combine your business and operational strategies into one allowing you to gain sharper insight and control of your data – leading to more intelligent decisions, safer conditions, increase efficiencies and greater profits.

Get Quote

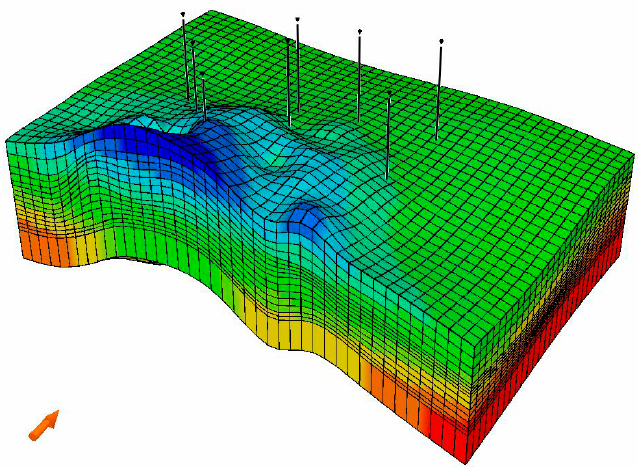

Dynamic Simulation

Deliver dynamic simulation solutions with Mimic Simulation Software Dynamic simulation with Mimic Simulation Software provides accurate and real-time simulation of plant behaviors. Made for users with process automation experience, not simulation experts, Mimic automatically integrates with DeltaV or other offline control systems. Use the exact same operator graphics and controls to test configurations and train new or inexperienced operators. For more information on how Mimic supports Emerson’s Digital Twin solutions, refer to the white paper “Emerson Digital Twin: A Key Technology for Digital Transformation.”

Get Quote

Control & Operator Performance

Maximize Your Plant To compete in today’s markets, your team must continually find and implement process improvement. For many organizations, in-house staff is over allocated, and expertise is stretched. Control and operator performance experts help deliver operational certainty with improved run time and startups / shutdowns, as well as increased quality and throughput.

Get Quote